What are Polymers

Polymers are materials made up of large repeating molecules and are used in a wide variety of items we use as part of our everyday life, ranging from smartphones to skincare. Polymers can be natural or artificial. However, traditional manufacturing methods have not provided the precision required to keep up with modern polymer demands, resulting in a lack of control over molecular structure and properties. However, new technologies such as RAFT Polymers are helping to combat these issues.

What is RAFT?

RAFT stands for Reversible Addition-Fragmentation Chain Transfer. RAFT polymerization is a controlled radical polymerization technique that revolutionizes the synthesis of polymers with precise control over their molecular weight and architecture. At the heart of RAFT polymerisation is the role of RAFT agents, which act as mediators to regulate the growth of polymer chains. These agents possess a unique structure, typically containing a thiocarbonylthio group, that forms a reversible bond with the growing polymer chain. This reversible bond allows for a dynamic equilibrium between dormant and active species, enabling control over the polymerisation process.

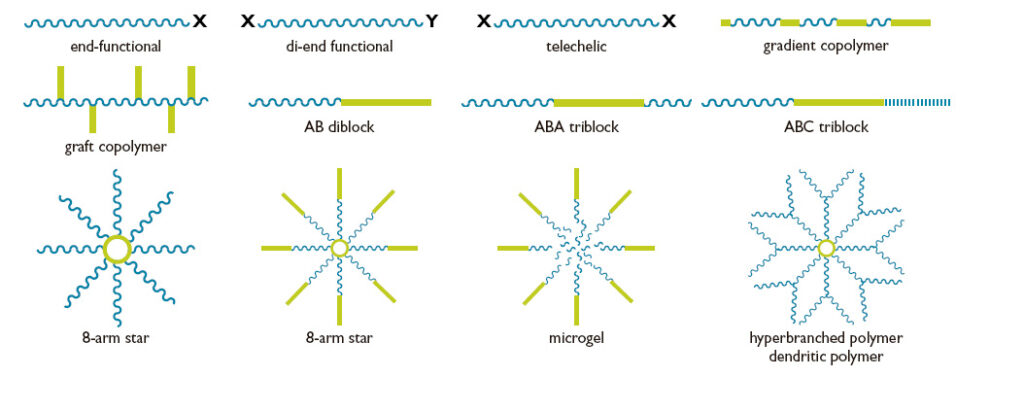

By carefully selecting and manipulating the RAFT agent, polymer chemists can fine-tune the reaction conditions and control the polymerization rate, resulting in well-defined polymers with controlled molecular weight distributions. This level of control allows for the synthesis of complex polymer architectures, such as block copolymers and graft copolymers, opening new possibilities for tailored material properties. The versatility and precision offered by RAFT polymerization have made it a highly valuable tool in polymer chemistry and materials science, enabling researchers to create advanced materials with tailored properties for a wide range of applications.

Advantages of RAFT Polymer technology

The key advantage of RAFT polymerisation is its ability to achieve precise control over the polymerization process, resulting in polymers with controlled molecular weight, low polydispersity, and tailored end-group functionality. This control enables the synthesis of complex polymer architectures, such as block copolymers and graft copolymers, as well as the incorporation of functional groups or stimuli-responsive segments into the polymer structure.

RAFT technology allows for convenient scalability using standard processing equipment, providing polymer chemists with the advantage of readily synthesising polymers with predetermined molecular weight and narrow molecular weight distributions across a diverse range of monomers and reaction conditions. Additionally, RAFT enables the deliberate manipulation of reactive terminal groups, including the potential for further polymerization, allowing for tailored modifications. Moreover, RAFT offers the ability to create polymers with intricate and complex architectures, unlocking new possibilities in material design and functionality.

Types of RAFT Polymers:

RAFT polymerization offers a wide range of possibilities for synthesising different types of polymers, including homopolymers and copolymers. Homopolymers consist of a single monomer, enabling the creation of polymer chains that possess uniform properties and well-defined structures. Copolymers, on the other hand, are formed by the polymerisation of two or more different monomers, leading to the incorporation of multiple monomer units along the polymer chain. This versatility enables the creation of copolymers with tailored properties, such as improved mechanical strength, thermal stability, or responsiveness to external stimuli. The synthesis of block copolymers, which involves the connection of different polymer blocks with distinct properties in a specific sequence, is made possible through RAFT polymerisation. Researchers can tailor the structure and properties of polymers to meet the specific requirements of various applications.

Applications of RAFT Polymers:

The diverse applications of RAFT polymers span numerous industries, showcasing their versatility and potential for innovation. In the field of drug delivery, RAFT polymers play a crucial role in formulating controlled release systems. By designing polymers with specific architectures and properties, researchers can achieve precise control over drug release kinetics, enhancing therapeutic efficacy and minimising side effects. RAFT polymers are also extensively used in biomaterials, where their ability to tailor material properties such as biocompatibility and biodegradability is highly valuable. The utilisation of these polymers in tissue engineering scaffolds, implants, and regenerative medicine enables the advancement of advanced biomedical solutions.

Furthermore, RAFT polymers find applications in coatings and surface modification, providing functional and protective layers with tailored properties. This includes the development of antifouling coatings, adhesives, rheology modifiers, responsive surfaces, and stimuli-responsive materials. The benefits of RAFT polymers extend to fields like sensors, microelectronics, and energy storage, where their controlled structure and functionalisation enable improved performance and device integration. Overall, the applications of RAFT polymers continue to expand, addressing critical challenges in diverse industries and driving innovation in materials science and technology.

Do you need a RAFT Polymer manufacturer?

If you need the highest quality chemical products, including RAFT polymers or agents? Look no further than Boron Molecular. Our leading boronic acid and fine chemical manufacturing facility has the capability to produce RAFT Agents and polymers to meet your commercial needs. Additionally, we offer custom synthesis for specialised compounds, this includes heteroaromatic chemistry, high-purity ionic liquid electrolytes, and much, much more!

For United States customers contact us today via email: sales@boronmolecular.com or call on +919 981 4441

For Australian customers, contact us today via email: sales@boronmolecular.com or call on +613 8558 8000.