Monomers and Polymers

Monomers and Polymers

Boron Molecular can undertake custom synthesis of monomers and polymers on scales ranging from grams (laboratory scale), to kilograms (pilot scale), through to commercial scale (hundreds of kilos to metric tonnes) to support all phases of development and manufacture. We can develop and optimize your process to ensure a smooth transition from laboratory scale through to pilot and commercial scale manufacture.

We work under non-disclosure agreements and don’t hold any IP on the processes developed under such agreements. Our objective is to build close partnerships with companies in order to solve your technical problems and to deliver high quality products. Ensuring the quality of our products is important to Boron Molecular.

We operate an ISO9001 quality system and we have an in house analytical laboratory that can perform a variety of analytical tests. We are currently supporting customers in a wide range of fields ranging from paints, coatings, adhesives and electronics through to cosmetic, veterinary and pharmaceutical industries.

Technology

Boron Molecular is able to offer custom manufacture of polymers to your specific requirements using RAFT polymerization, and anionic polymerisation. Boron Molecular’s ability to supply RAFT Agents (chain transfer agents for free radical polymerisation) at commercial scale provides a seamless progression from monomers to polymers at any scale. We have the analytical capability to analyze small molecular weight monomers by 1H NMR and GC and polymers by size exclusion chromatography (GPC).

RAFT Polymerization

RAFT (Reversible Addition Fragmentation chain Transfer) polymerization technology represents a versatile controlled radical polymerisation (CRP) technique for making polymers.

This technology has revolutionized polymer synthesis and spawned a new generation of polymeric materials, with many new applications in a wide range of fields including engineering materials, electronics, healthcare and biotechnology expected.

Using RAFT polymerization technology (RAFT) the production of well-defined, end-functionalized polymers, with precisely controlled structure, molecular weight, polydispersity, and with varied functionality can be easily achieved. RAFT is tolerant to a wide variety of reaction conditions and functionalities, and can be performed on existing conventional free-radical polymerization equipment.

Anionic Polymerization

Anionic polymerization is a type of “living” chain-growth addition polymerisation technique in which the active propagating centres are anions, involving the reaction of anionic initiators, typically alkyl lithiums, and vinyl monomers. Like RAFT technology, anionic polymerisation allows for the control of structure and composition of the product polymer.

A practical limitation anionic polymerization involves the very strict experimental requirements to ensure survival of the propagation anionic species. To this end,

Boron Molecular is working closely with CSIRO to develop the use of flow chemistry in the manufacture of polymers by anionic polymerization techniques to help overcome the difficulties with maintaining of stringent reactions conditions to ensure optimal and reproducible outcomes..

Polymers

PHMO

Boron Molecular can provide polyhexamethylene oxide (PHMO), a 1,6-hexanediol based polyether with a molecular weight in the 650-750 range. PHMO is used as a raw material in the manufacture of biomedical polyurethanes (Elast-EonTM).

PDMS

Boron Molecular can supply polydimethylsiloxanes (PDMS),a silicone based polymer. PDMS has applications as a surfactant, anti-foaming agent, hydraulic fluid and in lithography, medicines and cosmetics. PDMS can be reacted with polyhexamethylene oxide (PHMO) to produce a polyurethane elastomer, which has biomedical applications (Elast-EonTM)

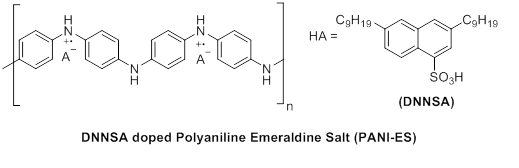

POLYANILINES

Solution processable polyanilines

Polyaniline (PANI) is a semi-flexible, rod-type, conducting polymer with high intrinsic electrical conductivity. PANI is unique among conducting polymers in that its conductivity can be reversibly controlled either electrochemically or chemically. Commercial applications of polyaniline include, electrostatic dissipation, anticorrosion coatings, rechargeable batteries, various electronic devices, sensor, organic photovoltaics, and separation membranes. The widespread use of PANI, however, has been severely hampered by its limited organic solution processability.

Boron Molecular can now provide xylene soluble solutions of doped PANI emeraldine salts in commercial quantities.

Dopant: Dinonylnaphthalene sulfonic acid (DNNSA)

Molecular Weight: MP 55,000; Mn 43,000; Mw 66,000.

Polydispersity: 1.52

Conductivity: 10 S/cm (thin film)

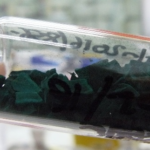

Colour/UV-Vis transmission: Dark emerald green

Processability: Soluble – xylene, toluene, NMP

Insoluble – water, acetone, 2-propanol

Production: Continuous production @100g/h with no run to run variation